Features

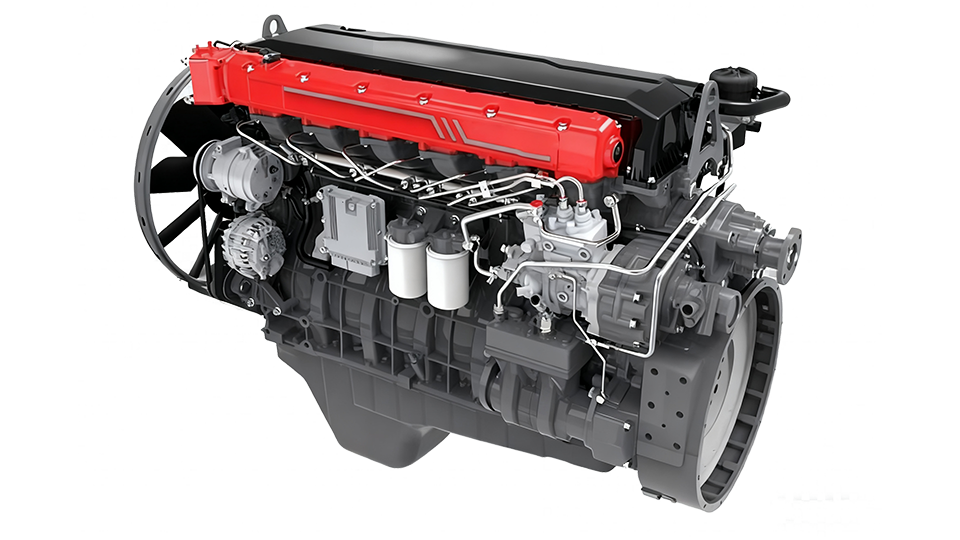

· The upper assembly is equipped with a Deutz engine with a total power of 365kW, featuring powerful performance, stable material suction negative pressure, and large suction air volume.

· The engine is directly connected to the vacuum pump pulley for drive, reducing energy loss, achieving high transmission efficiency, and effectively minimizing vibration transmission.

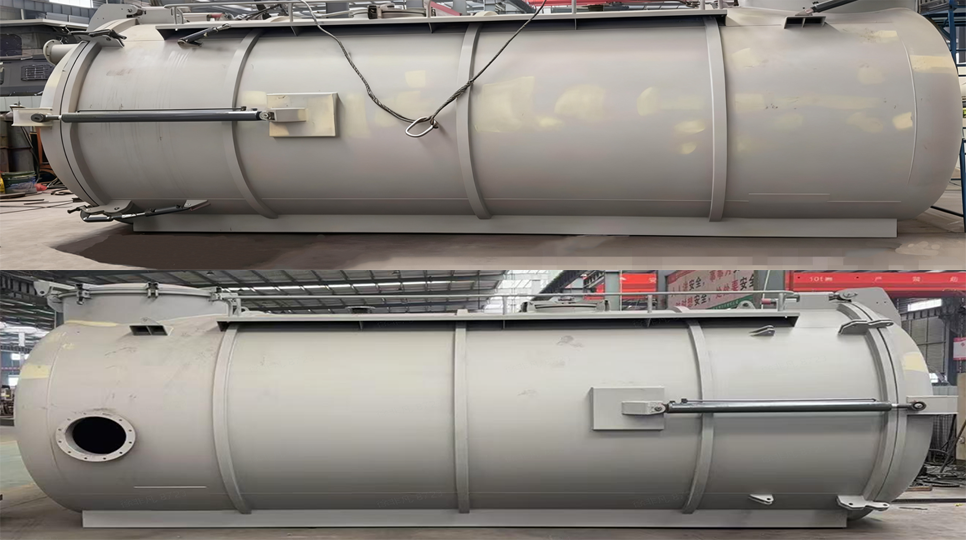

· The tank adopts a single-tank design with high space utilization of the upper assembly. The internal fluid flow field is optimized, ensuring strong dust conveying capacity, excellent gas-solid two-phase separation effect, and low comprehensive operation energy consumption.

· The tank features an external stiffener structure, and the circular tank has high strength. The inner wall of the tank is smooth and flat, allowing unobstructed unloading with convenience and low residue rate.

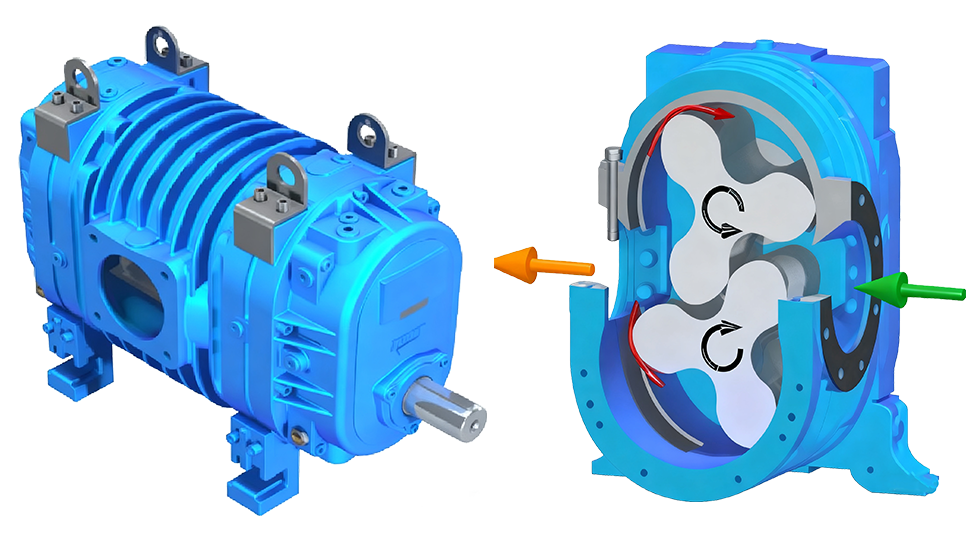

· Vacuum Suction System: Adopts high-quality domestic vehicle-mounted 3-lobe Roots vacuum pump, boasting high efficiency, stable air flow, low noise and high reliability .

· High-density dust filter bags with appropriate air permeability and excellent dust removal effect. The bags are equipped with reverse-blowing ash cleaning function, ensuring a long service life.

· The control box adopts electrical control integration technology, eliminating the need for hydraulic multi-way valve operation , enabling simple and convenient operation.

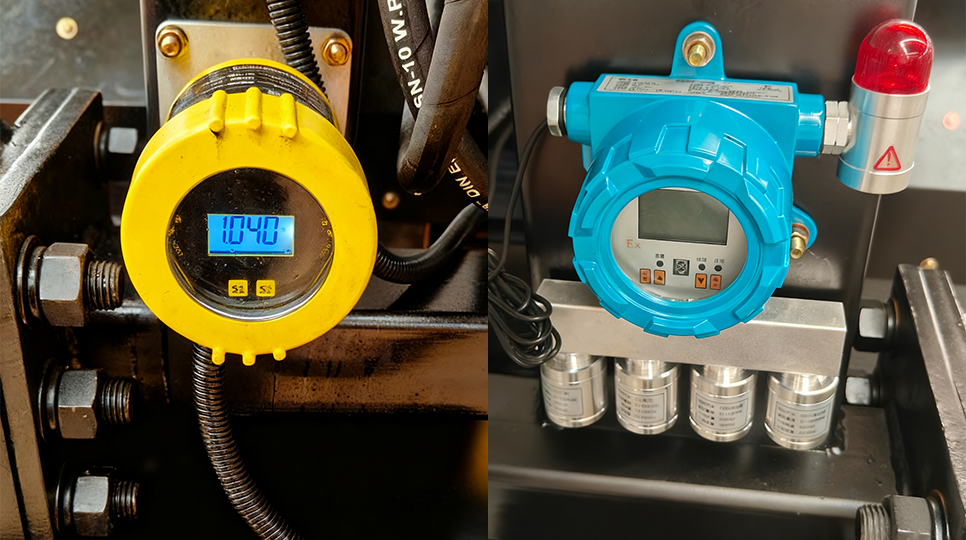

· Equipped with in-tank material level display and alarm function, which triggers an alarm when the tank is full. The gas detection instrument is linked to the electronic control system, allowing direct shutdown of the engine for maximum safety guarantee.

_095318.png?x-oss-process=image/format,webp)