Features

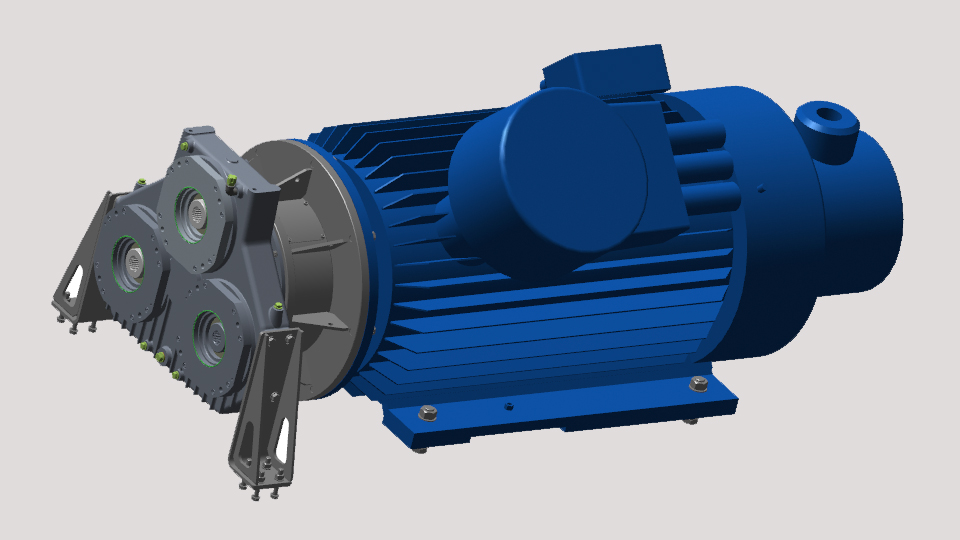

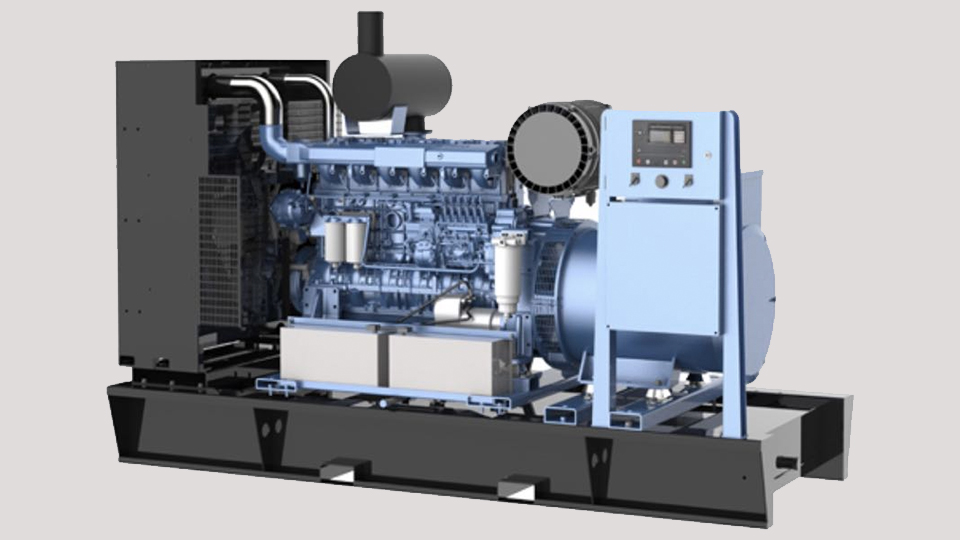

· Equipped with two 450kW explosion-proof variable frequency motors, delivering 12.5% more power than competitors;Featuring the world’s first variable-speed shifting cylinder technology, tripping speed is increased by 25%; Compared to diesel engines, electric motors reduce energy consumption by over 50%.

· Equipped with mud manifold, air manifold, foam pump, and other systems to support various drilling methods, including mud drilling, air drilling, foam drilling, and reverse circulation with air.

· The main unit’s three-module design, combined with the accessory trailer, requires only four truckloads for transport. The system features simplified assembly and integrated self- propelled walking capability for short-distance repositioning after installation;Low-position assembly and automatic hoisting mechanism minimize the risks associated with high-altitude installation

· Equipped with an integrated display screen for real-time visualization and monitoring of key drilling parameters, enabling automatic pressure adjustment during drilling operations;One-touch integrated control, featuring multiple tool integration and interlocking, allowing a single-operator to perform fully automated control of both the main equipment and auxiliary units