What Is a Crane Boom? A Detailed Look at its Types, Working Principles, and Buying Strategies

This article explains what a crane boom is, its types, working principles, and how to choose one, helping you choose the right boom for your project.

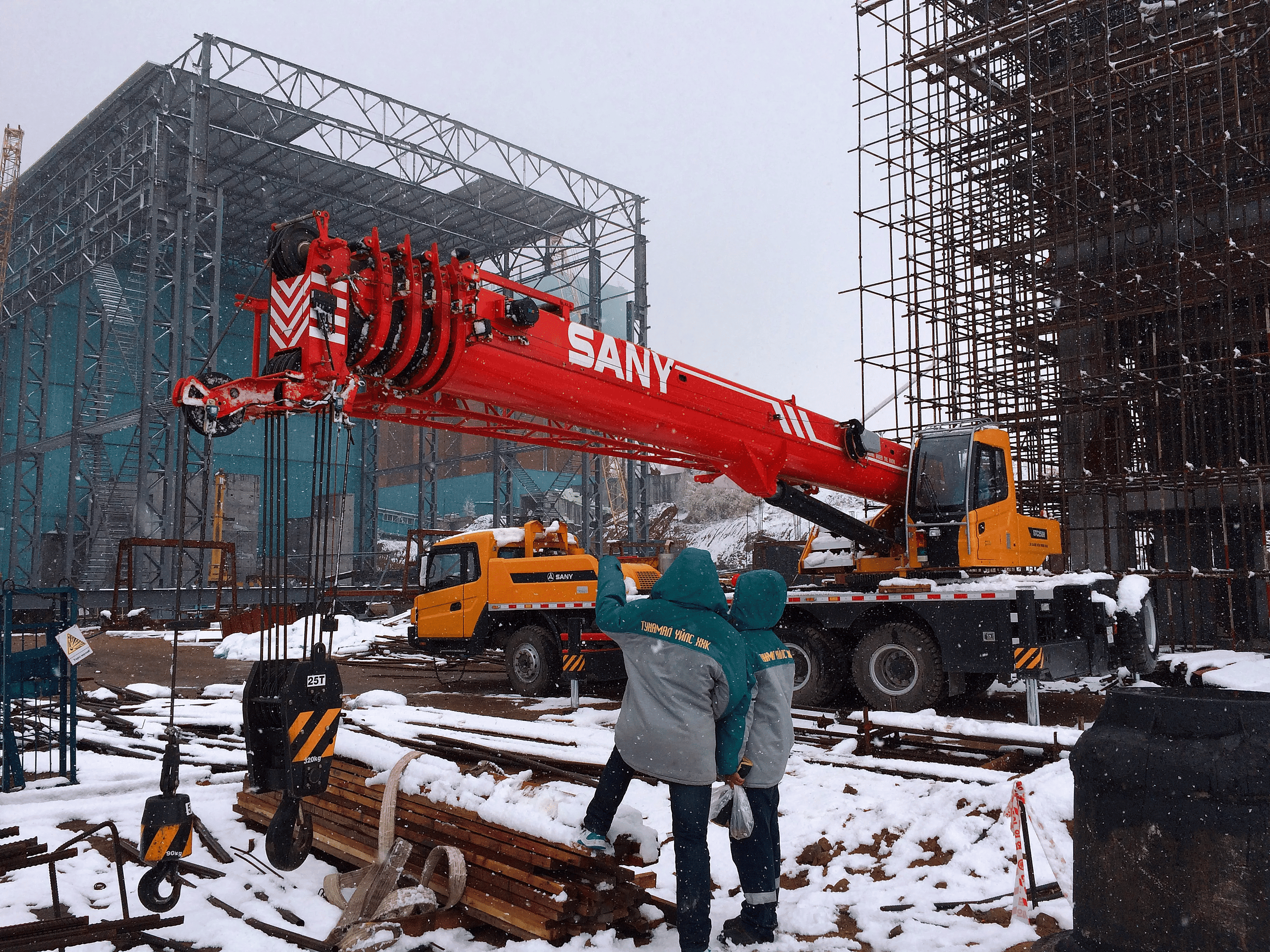

On construction sites, crane booms flexibly adjust their length to precisely deliver steel and building materials high into the air. Within logistics and warehousing parks, boom trucks quickly lift containers and heavy cargo for transport to their destinations. In these scenarios, the crane boom is a core operating component, its performance directly impacting operational efficiency and safety. So, what is a crane boom? How does it lift and lower heavy loads and adjust its boom length? What are the different types of crane booms? What's the difference between a crane boom and a boom truck? The following article will delve into these questions.

(1)_153548.png)

What Is a Boom Crane?

The crane's boom, the core load-bearing and operational component, is a long fixed or hydraulic arm used to lift and move large objects during construction. It provides the crane with ample reach, enabling construction workers to reach high-rise buildings or inaccessible areas, safely handle large or heavy materials, and adapt to varying work environments and space constraints.

How Does a Crane Boom Work?

A crane boom primarily operates by amplifying and transferring force through levers, pulleys, and hydraulic or mechanical systems to lift and transport heavy objects. The pulleys at the top of the boom, coupled with ropes and a winch, provide mechanical advantage, enabling a small pull to lift a significant weight. Furthermore, by extending, luffing, and rotating the boom, the boom can vary its operating radius and lifting height, allowing it to precisely move heavy objects to a desired location. The following is the crane boom operation process:

Preparation: Check that all crane components (including the boom) are functioning properly.

Movement: Use the crane's travel or outrigger mechanisms to move the crane to the work site.

Lifting: Operate the lifting, slewing, telescopic, and luffing mechanisms to position the boom to the desired location.

Hoisting: Activate the winch and lift the load via the pulley system.

Moving and Placing: Using the boom and other mechanisms, move the load to the desired location and then lower it.

Main Types of Crane Booms

In different operating scenarios, such as construction, ports, and factories, crane booms employ differentiated structural designs based on load levels, operating radius requirements, and on-site space conditions to meet these requirements. In the current civil engineering and construction industries, crane booms are primarily categorized as telescopic booms, lattice booms, folding booms, and fixed booms.

Telescopic Boom

Structural Design: Composed of multiple parts, it utilizes a telescopic structure similar to a telescope, enabling flexible adjustment of boom length.

Performance Features: It can freely adjust its length and operating height based on operational needs, offering high flexibility and quick adaptation to varying operating parameters.

Lattice Boom

Structural Design: This boom is constructed from multiple welded high-strength steel webs, typically forming a "W" or "V" shape. This not only enhances boom strength but also reduces weight. The truss design provides longer reach and greater lifting capacity.

Performance Features: Fixed length, capable of rotation, tilt, and left-right movement. Precisely calculated tilt angles ensure stability, and safe operation is achieved through the cab-controlled control system and hoisting system.

Folding Boom

Structural Design: The folding boom, also known as an articulated boom or curved boom, utilizes a multi-joint tandem structure that supports folding movement. Its bending and extending motion is similar to the movement of human fingers, allowing for flexible changes in the arm's shape through joint linkage.

Performance Features: Its core advantage lies in its high maneuverability. The multi-joint design allows for flexible adjustment of the working angle and arm positioning, enabling multi-angle and multi-position operations within complex spaces, providing remarkable operational flexibility.

Fixed Boom

Structural Design: No telescopic or folding joints are required; the arm is a fixed, integrated structure. The overall construction is simple and requires minimal integration, eliminating the need for complex telescopic and bending drive components.

Performance: Highly practical and stable. With no moving parts, the risk of failure is low, and maintenance is easy. However, the arm's functionality is relatively limited, and the arm length and working angle are fixed, preventing adjustments to reach and height.

Crane Booms vs. Boom Trucks—What’s the Difference?

In addition to crane booms, truck cranes are also commonly used in lifting operations, and many people confuse the distinction between the two. From functional positioning to application scenarios, crane booms and truck cranes differ significantly. The following will further analyze their core differences.

Different Definitions

Although both crane booms and truck-mounted cranes are suitable for lifting, they fall into different equipment categories.

Crane boom: A crane component, the mechanical arm used for lifting.

Truck crane: A specialized vehicle that combines a crane boom with a truck chassis and cargo box, also known as a truck-mounted crane transporter.

Different usage scenarios

Crane boom: Its primary functions are extension, lifting, and rotation. The hook or attachment at the end is used to lift and transport cargo.

Truck crane: It combines lifting and transportation functions, enabling both loading and unloading with a crane and transporting cargo with a container. It can also travel at high speeds.

Differences in Features

Crane boom: The boom itself is a single component and does not have independent transport capabilities.

Truck crane: Combining the functions of a crane and a truck, it improves resource utilization and enables multiple uses. It also offers high flexibility, enabling lifting operations in both wide and flat areas as well as in confined spaces like warehouses and docks. It is also easy to transport and can handle long-distance transport, such as on highways, making it suitable for a variety of scenarios, including logistics and landscaping projects.

For example, SANY has truck cranes with different lifting capacities, including truck cranes below 45T, 50T~90T, and above 90T. Their advantages in various aspects are very significant.

For example, SANY's Below 45T Truck Crane, with their compact design, can easily access various urban or small construction sites. Their task-oriented mobility and flexibility enable construction workers to fully carry out projects. They have a maximum lifting capacity of 16 to 45 tons, a maximum boom length of 32 to 45 meters, and a maximum lifting height of 40.5 to 60.5 meters.

In terms of operational performance, it features a dual-pump intelligent flow distribution system. This electro-hydraulic control system enables effective flow distribution, resulting in fast combined action response, minimal impact, and energy conservation and environmental protection. Furthermore, it boasts precise control and excellent inching performance, with a minimum stable single-rope speed of 1.2 m/min and a minimum rotational speed of 0.1/s. Integrated slewing buffer control ensures smooth and easy starting and stopping. Furthermore, it boasts a high-performance, innovative structural frame, proven through 200,000-cycle fatigue testing, for enhanced operational reliability.

How to Choose the Right Type of Boom for Your Project?

Choosing the right boom type requires comprehensive consideration of factors such as lifting load, operating range, space limitations, operating environment, and transportation requirements, ensuring that the boom characteristics accurately match the actual needs of the project. The following are key considerations:

1. Determine Lifting Requirements

Load Capacity: Determine the maximum weight of the objects you need to lift.

Lift Height and Reach: Determine the maximum height you need to reach and the horizontal distance the boom needs to cover.

Frequency of Operation: Will you need to lift frequently or only occasionally? High-frequency operation may require more durable equipment.

2. Assess the Work Environment

Space Constraints: Is the work area confined? Are there any obstructions? Will you need to utilize wall space?

Ground Conditions: Is the ground flat and stable? This will determine whether a fixed crane is required.

Special Conditions: Are there any special operating requirements or restrictions, such as whether the operation will be indoors or outdoors?

3. Choose the right boom type

Telescopic boom: Suitable for small to medium-sized lifts, operations in confined spaces such as basement equipment, heavy indoor ceiling installations, and high-frequency, flexible operations such as warehouse transfers and handling materials on small construction sites.

Truss boom: Suitable for heavy lifts, ultra-high-altitude operations such as wind turbine towers and high-rise steel structures, and harsh outdoor environments such as coastal ports and large construction sites.

Folding boom: Suitable for mobile operations such as vehicle rescue, ship loading and unloading, confined spaces such as residential air conditioning, heavy indoor furniture handling, and temporary emergency operations such as emergency cleanup and traffic light maintenance.

Fixed-jib cranes: They are suitable for securing light loads such as warehouse unloading, workshop transfers, low-cost loading and unloading for businesses, farm machinery handling, and simple temporary operations such as scaffolding and light equipment relocation.

Truck cranes: They are suitable for various scenarios requiring heavy loads to be lifted or moved to different locations, such as construction projects, power line maintenance, roadside assistance, port operations, logistics handling, and general building repair and installation.

4. Consider Budget and Installation

Cost-effectiveness: Evaluate your budget and choose the most cost-effective solution.

Installation requirements: Consider the equipment's installation method. Some cranes require a fixed foundation, while others are portable or temporary.

Conclusion

To summarize, what is a crane boom? Crane booms are the core of lifting operations. They come in a variety of types, distinct from truck-mounted cranes. In actual projects, only by carefully selecting the appropriate boom type, taking into account factors such as lifting requirements and the working environment, can efficiency and safety be guaranteed. We recommend thorough pre-operation evaluation, selecting the appropriate boom based on specific working conditions, and ensuring thorough equipment inspection and maintenance. This ensures that the crane boom is fully utilized in various scenarios and helps projects proceed smoothly.

FAQs

What is the difference between a crane jib and a crane boom?

The crane boom is the main heavy arm of the crane, used for initial lifting and long-distance movement of heavy loads. The crane jib is an auxiliary arm, usually smaller and telescopic, attached to the end of the boom to provide additional reach when the load capacity is reduced, enabling lifting at higher or farther locations.

Can you walk under a crane boom?

No, you must never walk under a crane boom. Especially when a load is suspended or the crane is in operation. This includes the entire crane, the area beneath the boom, whether loaded or empty, and the crane’s slewing radius to prevent accidents and potential malfunctions.

What are the two most common crane booms?

The two most common types of crane booms are lattice booms and telescopic booms. Lattice booms are sturdy structures made of steel trusses and are used for heavy lifting and long-distance operations, while hydraulic booms, or telescopic booms, use telescopic sections that are extended by hydraulic pressure, providing flexibility and easier transportation for a variety of tasks.

What is a crane boom used for?

A crane's boom is the long arm of a crane, used to lift, move, and place heavy objects on a construction site. The jib enables the crane to reach, enabling it to carry materials above and below the construction site. It is a critical component for heavy lifting, and the type of boom chosen depends on the specific project requirements for reach, flexibility, and lifting capacity.