A Guide to the Forklift Industry: Types of Forklift Trucks, Selection Skills, and Future Trends

Starting from the system of types of forklift trucks, this article explains the scientific selection methods and provides a comprehensive insight into the past, present, and future of forklifts.

Forklifts are indispensable in every link of logistics transportation and industrial production. They can move flexibly in warehouses to stack goods, operate steadily in construction sites to transport heavy materials, and serve as key equipment in port loading and unloading operations. However, forklifts are not of a single type. Different operating environments, cargo characteristics, and efficiency requirements correspond to different types of forklift trucks.

For example, narrow indoor warehouses are suitable for flexible reach trucks, while rough outdoor construction sites require durable off-road forklifts. With the continuous advancement of technology, the forklift industry is undergoing a transformation towards automation, new energy, and intelligent system. Leading enterprises in the industry, such as SANY, have taken the lead in introducing innovative forklift products that lead the future, providing strong support for upgrading logistics and industrial operations.

Types of Forklift Trucks by Specific Design and Function

There are several ways to classify different types of forklift trucks, among which "design function" and "OSHA standards" are the two most commonly used methods. The former focuses on "application adaptation", while the latter emphasizes "safety and compliance". Combining the two can meet the needs of most operating scenarios.

1. Classification by Design Function: 9 Common Types of Forklifts

This classification method directly corresponds to the core operational needs and serves as the most intuitive reference for practical forklift selection.

- Counterbalance Forklifts: The most versatile type of forklift, equipped with a counterweight at the rear to ensure stability, with a load capacity ranging from 1.2 to 52 tons. They can be powered by internal combustion engines or electricity, suitable for outdoor areas, workshops and other scenarios with no special requirements for exhaust gas and noise, and can perform various operations such as handling and stacking.

- Reach Forklifts: The forks and mast can move forward as a whole. When retracted, the operating aisle only needs 2.7 to 3.2 meters, and the lifting height can reach 11 meters. Powered by electricity, they have a small turning radius and are the first choice for maximizing space utilization in warehouses with dense shelves.

- Order Picker Forklifts: Specifically designed for order picking, they are divided into low-level (within 2.5 meters) and medium-to-high-level (up to 10 meters) types. Operators can lift and lower with the forks to pick goods directly from shelves, with a load capacity of 1.0 to 2.5 tons, greatly improving piece-picking efficiency in warehouses.

- Rough Terrain Forklifts: With inherent all-terrain properties, they have large ground clearance, strong tires, and are adapted to diesel power. They can operate on rough ground such as construction sites and farms, and are resistant to dust, high and low temperatures, making them exclusive handling tools for complex outdoor environments.

- Pallet Jacks: Focused on short-distance horizontal handling, with a load capacity of 1.6 to 3.0 tons, and a fork lifting height is about 210mm. Available in manual and electric versions, they are easy to operate and low in cost, suitable for the turnover, palletized goods turnover in warehouses.

- Walkie Stackers: Featuring a simple structure and affordable cost, they come in manual and electric versions, with a load capacity of 1.0 to 1.6 tons and a stacking height of 2 to 5 meters. Ideal for short-distance handling and basic stacking operations in small warehouses.

- Telescopic Handler Forklifts: Equipped with a telescopic boom to reach high altitudes and handle goods over distances. Adapted to high-altitude loading and unloading scenarios in construction sites and logistics centers, they offer high flexibility but requiring skilled operators..

- Side Loader Forklifts: With a unique side-forking design, they can handle long goods such as steel bars and wood, without turning, with a load capacity of 3.0 to 6.0 tons. Mostly powered by internal combustion engines, they are "specialized tools" for wood factories and steel warehouses.

2. Classification by OSHA Standards: 7 Categories of Compliant Forklifts

OSHA's classification standard focuses on "power type + tire type" and emphasizes safety compliance. It is a widely recognized classification system worldwide, especially suitable for operations with strict safety requirements.

- Class I - Electric Motor Rider Forklifts: Driven by an electric motor, available in seated or standing models, with optional solid or pneumatic tires. They produce no exhaust gas and have low noise, ideal for indoor environments requiring high air quality.

- Class II - Electric Motor Narrow Aisle Forklifts: Specifically designed for narrow aisles, including reach trucks, order pickers, turret trucks, etc., mostly equipped with solid tires. They can operate in aisles of 2-3 meters, and are key equipment for "efficient space utilization" in high-rise shelf warehouses.

- Class III - Electric Motor Hand Trucks / Hand/Rider Forklifts: Including electric stackers and pallet jacks. Some are ride-on, while others require walking alongside. They focus on short-distance handling, suitable for temporary storage and turnover of goods in warehouses, with a low operational threshold.

- Class IV - Internal Combustion Engine Forklifts (Solid/Cushion Tires): Equipped with internal combustion engines and solid or cushion tires, suitable for smooth indoor floors. Strong load capacity but emit exhaust gas.

- Class V - Internal Combustion Engine Forklifts (Pneumatic Tires): Also powered by internal combustion engines, but equipped with pneumatic tires, which have strong ground adaptability and can be used for both indoor and outdoor operations. They can cover everything from single pallet handling to container loading and unloading, and have the widest range of applications.

- Class VI - Electric/Internal Combustion Engine Tractors: Their core function is "traction" rather than "lifting". They can tow cargo trains or heavy-duty equipment, with optional electric or internal combustion power, suitable for long-distance traction operations in factories and warehouses.

- Class VII - Rough Terrain Forklifts: Consistent with the "rough terrain forklifts" classified by function, they are equipped with diesel power and durable pneumatic tires, specifically designed for rough outdoor environments. Suitable for construction sites, mines and other scenarios, they are the exclusive category for "outdoor heavy-duty operations" in the OSHA system.

How to Choose the Right Type of Forklift Truck for Your Job?

The core of forklift selection is "no wasted functions and no unmet needs". It requires starting from the three dimensions of environment, goods, and efficiency, narrowing down the scope step by step based on actual parameters, and finally locking in the optimal solution.

Step 1: Consider the Environmental Tone

The environment directly determines the forklift's power type and size adaptability:

- Indoor Scenarios: Prioritize electric forklifts, as they produce no exhaust gas and have low noise, avoiding pollution or impact on the working environment. If the aisles are narrow, choose reach trucks or narrow-aisle forklifts; if the aisles are wide, counterbalance forklifts are more flexible.

- Outdoor Scenarios: Prioritize internal combustion forklifts or rough terrain forklifts, which have strong battery life and resistance to harsh environments. If the ground is rough, rough terrain forklifts are a must; if the ground is flat, internal combustion forklifts with pneumatic tires are sufficient.

Step 2: Consider the Characteristics of the Loaded Goods

Goods are the "operation object" of the forklift, and their characteristics directly determine the forklift's load capacity and functional design:

- Choose Load Capacity by Weight: For light loads (≤2 tons), select pallet jacks or walkie stackers; for medium loads (2-8 tons), choose counterbalance forklifts or reach forklifts; for heavy loads (≥8 tons), select heavy-duty counterbalance forklifts or custom models.

- Choose Functions by Shape: For regular palletized goods, counterbalance forklifts and reach forklifts are versatile; for long goods, side loader forklifts are the optimal solution; for scattered and broken goods, order picker forklifts can greatly improve efficiency.

Step 3: Align with Efficiency Requirements

Efficiency requirements determine the "functional focus" of the forklift, avoiding "overkill" or "being overwhelmed":

- Stacking Height Requirement: For low stacking height (≤3 meters), use pallet jacks or walkie stackers; for medium-high stacking height (3-10 meters), use reach forklifts or counterbalance forklifts; for ultra-high stacking height (>10 meters), use narrow-aisle turret trucks.

- Handling Distance: For short distances (≤50 meters), use walkie stackers or electric pallet jacks; for long distances (>50 meters), use electric rider forklifts or internal combustion counterbalance forklifts to avoid frequent charging/refueling.

- Operational Continuity: For high-frequency continuous operations, such as in ports and logistics hubs, choose internal combustion forklifts—they refuel quickly and can operate 24 hours a day; for intermittent operations, such as in small warehouses, choose electric forklifts—they have lower maintenance costs and are more economical.

Step 4: Quick Decision-Making with a "Comparison Table"

If you need to quickly narrow down options, you can refer to the matching relationship between core needs and recommended types below:

Core Needs | Recommended Forklift Types | OSHA Classification Reference |

Narrow Indoor Aisles + High-Rise Racks | Reach Forklifts, Narrow Aisle Forklifts | Class II |

Rough Outdoor Terrain + Heavy Loads | Rough Terrain Forklifts, Internal Combustion Forklifts with Pneumatic Tires | Class V, Class VII |

Scattered Order Picking + Medium-Low Stacking | Order Picker Forklifts | Class II (Partially) |

Long-Shaped Cargo + Side Forking | Side Loader Forklifts | Class IV (Partially) |

Short-Distance Light Loads + Low Cost | Electric Pallet Jacks, Walkie Stackers | Class III |

Future-Leaning Types of Forklift Trucks: Automation, New Energy, and Intelligence Become Mainstream

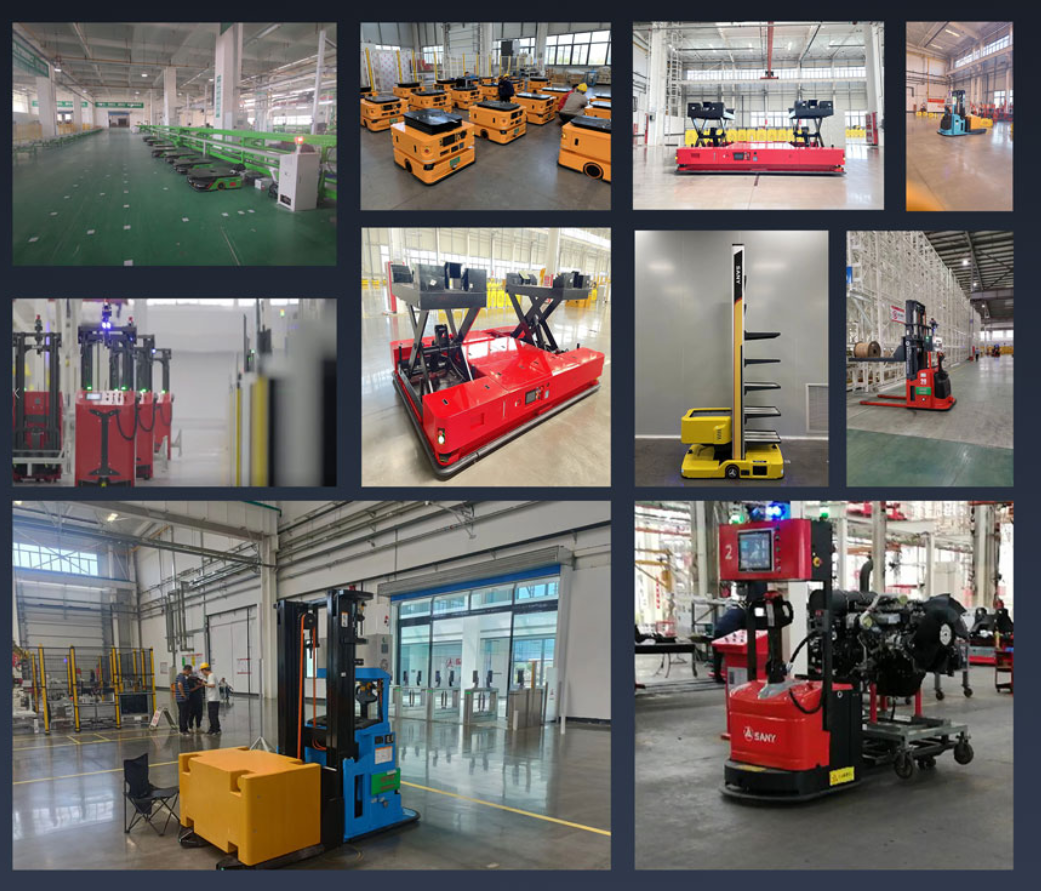

With the intelligent upgrading of logistics and industry, forklifts are no longer just single handling tools, but are gradually becoming intelligent units integrated into systems. As a world-leading equipment manufacturing enterprise, SANY has made in-depth layouts in the field of future forklift truck. Its product matrix fully reflects the development direction of automation, new energy, and intelligence, providing practical and implementable cases for the industry.

1. Fully Automatic Unmanned Forklifts

This type of forklift is completely independent of manual operation and will be the main force in large-scale intelligent warehouses in the future. SANY representative product in this field is the AGV forklift series, whose technical and application characteristics highlight its industry leadership.

2. New Energy Forklifts

Traditional internal combustion forklifts and lead-acid battery forklifts are gradually being replaced, while new energy forklifts focus on "environmental protection + high efficiency". Accurately grasping industry trends and driven by technological innovation, SANY has built an electric forklift product matrix covering multiple scenarios and needs around this core path, providing strong support for the green transformation of various industries.

3. Intelligent Human-Machine Collaborative Forklifts

For scenarios with complex types of goods where full automation is not feasible, "human-machine collaboration" is the optimal transitional solution. It retains manual operation while using intelligent technologies to assist in improving safety and efficiency. Based on traditional forklifts, SANY has also upgraded the Intelligent Forklift Truck series. Scenarios such as small and medium-sized warehouses, manufacturing workshops, and piece-picking operations can leverage this series to balance the flexibility of manual work and the safety of intelligence.

4. Specialized Forklifts for Segmented Scenarios

In the future, more "scenario-customized" forklifts will emerge. SANY has already launched various specialized products to address segmented needs such as extreme environments and compact spaces, and these products have gained customer recognition.

Conclusion

It can be said that forklifts are no longer just simple handling tools, but are gradually transitioning from traditional machines to intelligent system units integrated into logistics and industrial systems. They play an increasingly important role in improving operational efficiency, reducing costs, and promoting environmental protection. For enterprises, mastering the types of forklift trucks and selection methods, and paying attention to the future trends of the industry, can not only help select forklift equipment that meets their own needs, but also inject impetus into the long-term development of the enterprise. It is believed that, driven by the continuous advancement of technology, future forklifts will bring more surprises to the logistics and industrial industries, and promote the entire industry to move steadily towards a more efficient, more intelligent, and greener direction.

FAQs

What Forklift Type Is Best for Warehouses?

Counterbalance forklifts are the most commonly used type in warehouses, followed by reach forklifts. The specific selection should be based on warehouse space and operational requirements.

1. Counterbalance Forklifts

- They have a wide range of applicable scenarios and can be used universally in outdoor and indoor warehouses, capable of handling palletized goods and bulk goods.

- They do not rely on shelf support and have low requirements for the ground, making them suitable for daily loading, unloading, and stacking operations in most warehouses.

- The disadvantage is that they have a large turning radius and require more spacious aisle space to be reserved.

2. Reach Forklifts

- Their advantage lies in the fact that the forks can extend forward, and they have a small turning radius, making them suitable for dense warehouses with narrow aisles.

- They have a higher stacking height, which can fully utilize the vertical space of the warehouse and improve storage efficiency.

- The disadvantages are that they rely on flat ground, are usually only suitable for indoor operations, and their load capacity is slightly lower than that of counterbalance forklifts of the same level.

What Is the Most Common Type of Forklift Truck?

The most common type of forklift truck worldwide is the counterbalance forklift. Its popularity stems from its strong versatility and adaptability. It can operate in both indoor warehouses and outdoor sites, and handling palletized and non-palletized goods. Furthermore, it does not require external support such as shelves and has low requirements for ground conditions, which allows it to meet most material handling needs.

What Are the Three Main Types of Forklifts?

The three main types of forklifts are counterbalance forklifts, reach forklifts, and warehouse forklifts (such as stackers), each with a distinct focus on applicable scenarios.

1. Counterbalance Forklifts

- They have the strongest versatility and can operate indoors and outdoors.

- They rely on rear counterweights to maintain balance and do not require external support, making them suitable for most loading, unloading, and stacking needs.

- However, they need wider aisles for turning.

2. Reach Forklifts

- Their forks can extend forward, and they have a small turning radius and a higher stacking height.

- They can adapt to dense storage in narrow aisles.

- But they are mostly limited to indoor use and have higher requirements for ground flatness.

3. Warehouse Forklifts

- They focus on operations in low indoor spaces, with a compact size and flexible operation.

- They are mainly used for short-distance handling and low-height stacking in warehouses.

- Their load capacity is relatively low.

Featured Products

Recommend Blogs

What Is a Forklift Truck? Definition, Types and Working Principles

This guide will provide you with a comprehensive overview of forklift knowledge, giving you a clear understanding of what is a forklift truck.

Learn About Forklift Truck from Scratch and Master Core Points of Classification and Configuration

This guide explains what a forklift truck is, outlining its main functions, classification types and provides practical tips on how to buy forklift truck fits your needs.

How Much Does a Forklift Truck Weigh? A Quick & Practical Weight Data and Safety Guide

How much does a forklift truck weigh? Get typical weights, factors affecting them, and practical safety tips for operators.