2025 Targeted Guide: How Often Does a Periodic Crane Inspection Occur?

This guide will provide a detailed explanation of how often does a periodic crane inspection occur,to ensure equipment safety and prevent accidents.

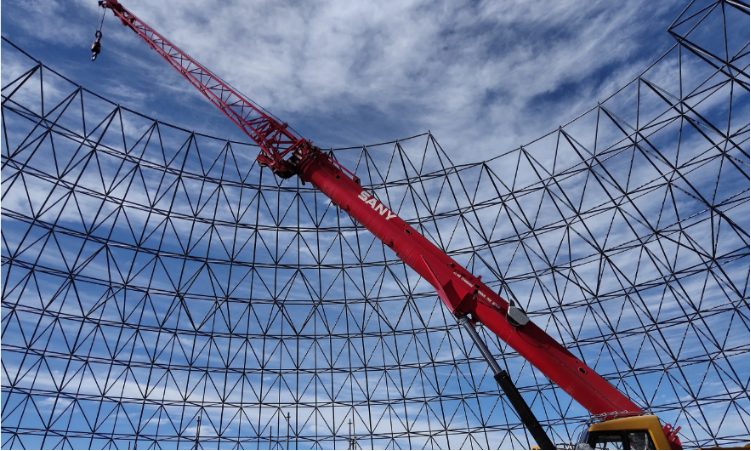

Cranes are critical heavy-duty equipment in industrial production and construction sites, and their operational safety is directly linked to the safety of personnel and property. Regular inspections are key to preventing equipment failures and avoiding safety incidents. Whether it’s the popular bridge cranes, gantry cranes, or the widely used truck cranes in construction projects (such as the Below 45T Truck Crane from SANY), standardized inspections are necessary to ensure safe operation.

So, how often does a periodic crane inspection occur? This article will explore this question, offering clear practical advice based on different working conditions and industry standards to help with equipment safety management.

What Types of Crane Inspections Exist?

Taking bridge cranes and gantry cranes as examples, to ensure their operational safety and optimal performance, four core inspections must be conducted in accordance with the Crane Manufacturers Association of America (CMAA) standard CMAA 78 and the ASME B30.2 standard. Each inspection type has a specific focus, and together, they form a comprehensive equipment safety management system.

Initial Inspection

The initial inspection is performed after a new crane is installed or after an existing crane has been repaired, modified, or had critical components replaced. It is carried out by original equipment manufacturer (OEM) professionals to verify that the safety and operational functions meet the design specifications before the equipment is put into service.

The inspection includes checking component installation gaps, operating speeds, lubrication levels of drive components, control device settings, and the effectiveness of safety devices such as limiters and emergency stop buttons. After completion, a formal report must be provided to the equipment owner. For modified or repaired equipment, a separate record should be made for affected areas, and the report must be archived for the full service life of the equipment.

Pre-Shift Inspection

Also known as the daily inspection or pre-operation inspection, this is conducted by crane operators who have received basic training before each work shift. If there are multiple shifts in a day, inspections should be conducted before each shift starts. The main goal is to identify immediate hazards.

The inspection should confirm that there are no out-of-service tags on the equipment, test lifting and movement functions to ensure they align with control settings, and visually inspect the hook (for cracks or deformations), wire ropes (for broken strands or tangles), and load chains (for wear or stretching). Additionally, the function of limit switches should be verified, and the equipment should be checked for unusual sounds during startup. Some companies may require the results to be recorded in paper or electronic form, and the operator is responsible for the inspection.

Frequent Inspection

Frequent inspections must be determined by various factors, including the crane’s usage frequency, operating environment, and the type and average weight of the loads being handled. So, when should a frequent crane inspection occur? According to ASME B30.2, frequent inspections are divided into three service levels with different inspection intervals:

Normal Use: Inspections are conducted every six months to half a year.

Heavy Use: Inspections are conducted monthly or weekly.

Severe Use: Inspections are conducted weekly or daily.

Who should inspect a crane? Inspections can be carried out by trained internal personnel or contracted to professionals from the OEM or third-party inspection agencies. The inspection content is similar to the daily pre-shift inspection but more detailed. All inspection items must be fully recorded, and the relevant reports should be kept for at least three years.

Regular Inspection

Regular inspections are usually performed quarterly, semi-annually, or annually, depending on the crane’s usage frequency, load characteristics, and operating environment. These inspections are carried out by the OEM or a third-party inspection agency.

The inspection content is comprehensive, covering the items included in the pre-shift and frequent inspections, as well as a detailed assessment of structural and mechanical components, including the main beam, end beams, walkways, guardrails, pulley frames, and operator’s cabin. The focus is on checking brakes, drive shafts, wheel axles, wheels, couplings, pulleys, drums, sliding track structures, and hook attachments for wear, cracks, or other damage. Electrical components, instruments, connectors, pulley tracks, bumpers, limit stops, safety devices, and all power units are also inspected.

All findings and results will form a report that is shared between the crane owner and the inspection agency. The report will document safety hazards, maintenance issues, and non-compliance, and it will include recommendations for corrective actions. If repairs are needed, the owner may seek a second opinion and decide who will perform the repairs.

The four types of inspections should be carried out in coordination. Inspectors must refer to historical documents to analyze equipment wear and failure patterns and optimize maintenance plans. This ensures that immediate risks are avoided, while long-term monitoring helps extend equipment lifespan, reduce total ownership costs, and ensures compliance with CMAA and ASME standards.

What Are the Requirements for Crane Inspectors?

According to the Crane Manufacturers Association of America (CMAA), crane inspectors must meet the following requirements:

On-Site Experience

Inspectors must have at least 2,000 hours of on-site experience directly related to crane maintenance, upkeep, repair, modification, and functional testing. Extensive field experience enables inspectors to better identify potential issues with equipment.

Training and Familiarity with Standards

Inspectors must have received appropriate training and be fully familiar with the applicable standards and regulations. Individuals who have not received relevant training or are unfamiliar with the standards are not allowed to conduct crane inspections.

Training in Specific Areas

- Safety and Design Standards: Inspectors must have training in safety and design standards related to overhead cranes, including the safety requirements during the crane's design, construction, and operation.

- Regulatory Standards: Inspectors must understand the federal, state, and local regulations to ensure that the inspections comply with various legal requirements.

- Safety Operation Standards: Inspectors must master the safety operation standards for cranes and hoists to assess whether the equipment's operation poses any safety risks.

- Report Writing: Inspectors must be able to write reports and follow documentation procedures to ensure inspection results are accurately and professionally recorded and communicated.

- Industry Terminology: Inspectors should be familiar with crane and hoist terminology to facilitate effective communication with other personnel during inspections.

Conclusion

How often does a periodic crane inspection occur? There is no fixed answer to this, as it depends on the characteristics of the four types of inspections: initial, pre-shift, frequent, and regular. It should be flexibly determined based on the equipment's working condition, usage intensity, and relevant standards like CMAA, ASME, etc. Moreover, inspection personnel need to have adequate on-site experience and professional training to ensure the quality of inspections. Only then can crane operation safety be fundamentally ensured, promptly addressing immediate risks and providing long-term maintenance to extend equipment lifespan, reduce accident prevention costs, and build a solid foundation for industrial production and construction safety.

FAQs

How often should regular crane inspections be performed?

The frequency of crane inspections depends on the level of usage, load characteristics, and operating environment.

Cranes with light loads and intermittent use are typically inspected once a year.

Cranes with medium loads and routine use are inspected every six months.

Cranes with heavy loads and high-intensity operation are inspected quarterly.

If the crane operates in harsh environments such as coastal areas with high salt exposure or chemical corrosion, the inspection cycle should be shortened by 30% compared to the above intervals.

What is the OSHA standard for crane inspection?

The core requirements of OSHA's crane inspection standards are as follows:

Frequent inspection: Must be performed before each use, focusing on key components such as hooks, wire ropes, and braking systems.

Periodic inspection: Should be carried out according to the crane’s usage frequency and load conditions. This involves a comprehensive review of structural, mechanical, and electrical systems to identify potential safety risks.

If the crane has undergone major repairs, modifications, or replacement of critical components, a special inspection is required to ensure the equipment’s safety performance meets the necessary standards.

Who is typically responsible for conducting a frequent inspection of cranes?

Frequent inspections are usually carried out by crane operators who have received basic training. In some companies, specially trained in-house personnel may be assigned to perform the task. If a company lacks qualified staff, the inspection can also be entrusted to the original equipment manufacturer (OEM) or professional third-party inspection agencies.

What are the two parts of a frequent crane inspection?

A frequent crane inspection mainly consists of two parts:

Visual inspection: Checking for physical damage and wear, while also ensuring there are no leaks in air or hydraulic systems and no signs of misalignment.

Functional testing: Verifying that all operating mechanisms (such as hoists, brakes, and control devices) work properly. This also includes checks on wire ropes and load chains.

Featured Products

Recommend Blogs

How Much Does a Crane Cost? A 2025 Full Breakdown by Crane Type

This article focuses on "how much does a crane cost in 2025", breaks down the costs of different crane types, offers buy or rent advice, and helps with making informed project decisions.

Types of Cranes: Your 2025 Comprehensive Guide to Every Major Category

As 2025's latest authoritative guide to types of cranes, this article breaks down the four types' core traits and application differences, giving engineers and equipment purchasers key selection criteria

How Are Cranes Built? A Step-by-Step Guide to the Construction Process

Cranes help us build towering skyscrapers, yet few know how cranes are built. This guide takes you through an in-depth exploration of the process