How Do They Get Cranes on Top of Buildings: Detailed Operation Guide

This article will revolve around the question how do they get cranes on top of buildings, common crane climbing methods, dismantling procedures, and operational safety precautions.

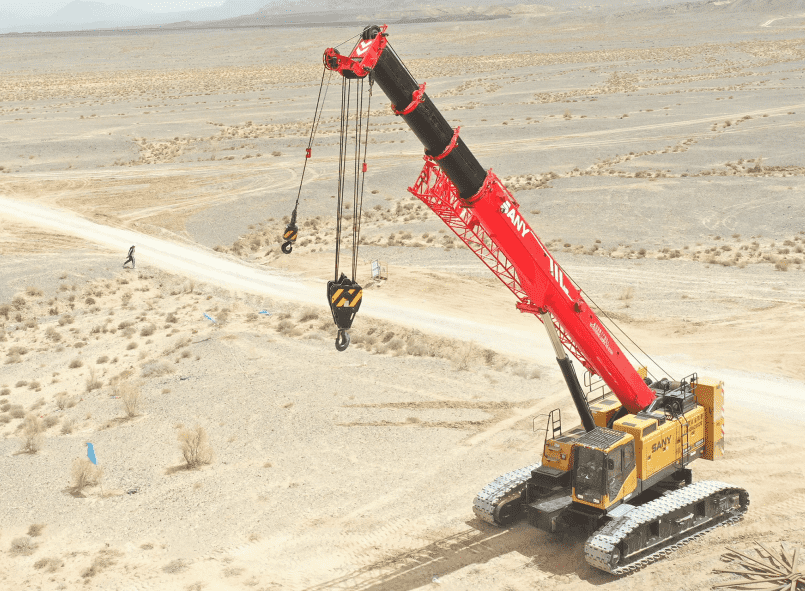

During the construction of high-rise buildings, the question how do they get cranes on top of buildings represents a core technical challenge, and directly affecting both construction efficiency and structural safety, and requiring customized professional solutions. Large lifting equipment represented by SANY crawler cranes cannot reach the top of the building directly due to their large weight and size, relying on conventional vertical transportation or horizontal handling methods. Specialized climbing technology must be employed, taking into account the building's structural characteristics, construction environment conditions, and height requirements to achieve deployment at the top. This article will systematically introduce several common ways of how do crane operators get to the top and explain the subsequent crane disassembly process and operational safety precautions.

Crane Climbing Methods

In high-rise building construction, how do cranes get to the top of buildings is not fixed but needs to be flexibly selected based on actual engineering conditions. From internal climbing and attaching to the building structure, to segmented lifting with the aid of auxiliary equipment, and dismantling and transporting using construction elevators or dedicated passages, there are various routes to the top, each with its applicable scenarios and technical characteristics. The following will provide a detailed introduction to these mainstream crane climbing methods.

External Climbing Method (Self-Climbing Cranes)

Definition: The external climbing method allows the crane (the boom and tower) to extend upward along the outside of the building. The specific steps involve first fixing the crane base to a concrete slab on the ground and positioning the crane tower next to the building. Then the crane tower extends upward along the outside of the building using steel rings and metal sleeves, gradually raising the crane base to reach the top.

Advantages: The external climbing method is the most efficient and fastest way to lift the crane to the top of the building, and it also allows the crane to gradually return to the ground after completing its work. There is no need to occupy the internal construction space of the building, making routine inspections, maintenance, and part replacements more convenient.

Limitations: The external climbing method is significantly affected by the natural environment, such as strong winds, heavy rain, and blizzards, which can directly interrupt operations and may increase the risk of tower shaking. Additionally, if the building is too tall, the tower needs to be spliced multiple times, which poses a greater test to its stability. Furthermore, the tower is exposed to the outdoors for a long time, making it susceptible to UV rays and rainwater corrosion, which also increases maintenance costs.

In terms of safe operation: before starting work, it is necessary to check one by one the wear of the steel sleeve, the metal sheath, and the tightness of the connecting bolts; the anchoring strength of the base to the concrete slab must meet design standards and be checked regularly; during the climbing process, the verticality of the tower must be monitored in real time, and wind speed recorded simultaneously. If limits are exceeded, work must be stopped immediately. Additionally, warnings should be set up on the ground to alert non-workers.

Internal Climbing Method

Definition: When external space around a building is limited, the internal climbing method is an effective approach, where the crane tower is positioned at the center of the building. Simply put, this method involves constructing a corridor, using hydraulic cylinders at the bottom to lift the crane, and employing steel beams to make it more stable. Subsequently, the crane can move layer by layer to construct the building around itself until it gradually reaches the top.

Advantages: The internal climbing method does not require external space of the building, making it suitable for densely populated urban areas or complex surrounding environments, reducing interference with surrounding traffic or residents' lives. Moreover, this method is less affected by external weather conditions and can still operate normally during strong winds and heavy rain.

Limitations: The internal climbing method relies on the construction of the floors, and it can only begin climbing operations once the concrete strength of the current floor reaches the design value and the steel beams are embedded. This process usually takes a long time to elevate the crane to the roof. Additionally, maintenance of the crane needs to be performed in a narrow internal space, making the operation difficult and inefficient.

In terms of safe operations: it is necessary to routinely inspect equipment, ensure sufficient ventilation in the work area, and install explosion-proof lighting to avoid personnel being deprived of oxygen or accidents caused by poor visibility. At the same time, workers should carry portable gas detectors to monitor the concentration of harmful gases such as carbon monoxide and methane in real-time.

Helicopter Lift (Skycrane Method)

Definition: The helicopter lift method can be used in certain special circumstances, such as remote or inaccessible construction areas. Helicopters can accurately lift and place heavy objects using long slings and bring cranes to the top of the construction site.

Advantages: The advantage of the helicopter lifting method lies in its ability to access remote areas without the need for roads or ground infrastructure, and it enables quick deployment and transfer of equipment and materials. It can also place cargo in a stationary position in narrow or crowded areas, and compared to traditional ground cranes, the helicopter lifting method has a smaller environmental impact.

Limitations: The limitations of the helicopter lift method are quite apparent, as helicopter flights are significantly affected by weather conditions. Moreover, lifting with helicopters must be done item by item, which is costly and time-consuming. It is very difficult to operate heavy-lift helicopters logistically in densely populated areas, so this method is relatively rare, and may only be used a few times a year.

In terms of safe operation: In addition to routine equipment inspections, the helicopter lift method requires a real-time monitoring mechanism to be established in collaboration with the meteorological department before each operation, updating weather data every 30 minutes to ensure that the entire operation is within a safe weather window. Moreover, when using the helicopter lift method, it is necessary to arrange professional ground command personnel to accurately guide the cargo's takeoff and landing positions, avoiding collisions with building structures and high-voltage lines.

How to Dismantle a Crane?

After the crane has completed the lifting operations at the top of the high-rise building, how can it be safely and efficiently dismantled and transported to the ground? It is recommended to develop a targeted dismantling plan based on the structural characteristics of the crane, such as whether it has a modular climbing section. The specific process is as follows:

Gradual Retraction: For cranes equipped with modular climbing sections or vertebral structures, gradually lower the height of the crane by incrementally retracting or removing the climbing sections.l

Segmental lowering: Once the crane height is reduced to a safe range, use a mobile crane or a heavy-duty helicopter to dismantle the cranes segment by segment and lower them to the ground or a lower level.

It is important to note that after the crane has been completely dismantled and removed, the staff need to carry out a thorough cleaning and restoration process of the construction site, including:

- Debris Clearance: Remove any remaining debris, materials, or equipment related to crane operations from the site. l

- Surface Repair: Concrete slabs, anchor points, or other surfaces affected by crane installation will be repaired or restored to their original condition.

- Site Inspection: Conduct a final inspection to ensure site safety and prepare for subsequent construction phases or occupancy.

Crane Operation and Safety Considerations

Whether it is the process of climbing to the top of the crane, the top work phase, or the subsequent dismantling stage, safety is always the core requirement throughout the entire process. Below are the key operating skills and safety precautions:

- Operators must be qualified: including having sufficient knowledge, experience, and the ability to handle unexpected situations; and regularly consult manuals and operating rules to understand how to properly use the equipment.

- Ensure safe operating conditions: When operating a crane, it is important to focus, for example, by turning off your phone in the cab to avoid distractions that could affect your work. Additionally, conduct a thorough inspection before operating to ensure there are no potential hazards on site.

- Before operating the handling equipment: It is crucial to check the condition of the handling and weighing equipment before starting operations. Check and confirm aspects such as the load radius before starting to avoid the probability of crane accidents and tipping incidents during operation.

- Prepare a detailed safety checklist before operation: Before starting to use the equipment, list the operational checklist that needs to be checked, and work can only begin after the checks are completed. The checklist should include verifying the load chart and ensuring a reliable safety assessment has been conducted.

- Ensure that the entire working area of the crane is clearly visible: pay special attention to the ground conditions during operation to ensure stability and safety. Make sure there is adequate visibility, with no blind spots, to always have complete control of the situation.

- Ensure that the load meets the equipment capacity: The load to be moved or lifted must be properly secured and comply with all safety measures related to shape and weight.

- Ensure safe operation of the crane and never stand under the load: When operating lifting equipment, placing yourself under the heavy object can lead to being struck by the object being lifted. Always maintain a safe distance from the load to be moved.

- Do not let the load hang in the air longer than necessary: Once you start moving, it's best to complete the movement as quickly as possible to avoid any accidents.

- Lift slowly and correctly: Throughout the process, avoid rushing and stay calm, do not accelerate or brake abruptly to prevent the cargo from swaying.

Conclusion

In summary, through the analysis of the technical principles and applicable scenarios of external climbing methods, internal climbing methods, and helicopter lifting methods, we believe everyone has a clear understanding of how do they get cranes on top of buildings. In actual operations, construction workers not only need to choose the appropriate climbing method according to the project conditions, but also must strictly follow regulations for the disassembly of cranes, and fully implement equipment inspections, environmental monitoring, and personnel operation requirements to ensure the safety and professionalism of lifting operations, thereby ensuring that the construction process progresses in an orderly manner.

FAQs

How do they get cranes off the top of buildings?

The crane can be dismantled from the top of the building using the "Russian doll" method, which proceeds as follows: first, a small crane is used to dismantle the large crane. Then an even smaller crane is hoisted to the roof, and this smaller crane is used for further disassembly. This process is repeated until the components are small enough to be lowered using a construction lift or ground-based crane. The dismantling process begins with the removal of the counterweight, followed by the gradual lowering and disassembly of the boom and mast sections.

How do they install cranes on buildings?

There are the following methods to install a crane on a building:

1.Use a second crane.

2.External climbing method.

3.Internal climbing method.

4.Use of a heavy-duty helicopter.

Why are there cranes on top of buildings?

The presence of a crane on top of a building is usually due to the need to transport heavy construction materials and components to great heights during high-rise construction. Cranes are an essential piece of equipment for this task, especially when building skyscrapers and other high-rise structures. Generally, a tower crane is used, which is attached to the main structure and can be raised in sync with the building.

What is a crane on top of a building called?

The crane at the top of the building is called a tower crane, characterized by its rotating tower and horizontal working arm, with a 360-degree rotation range, greatly simplifying construction work. Tower cranes are essential equipment for modern construction projects, enabling construction companies to work faster and more efficiently while easily handling heavy lifting tasks.

Featured Products

Recommend Blogs

What Are the Wheels on a Crane with Open Grooves? Analysis of Important Components of Cranes in 2025

What are the wheels on a crane with open grooves? What types of wheels exist, and how should they be maintained? This article will help you better understand these essential crane components.

When Were Cranes Invented: Tracing the Evolution of Lifting Technology Through the Ages

This article comprehensively explores every innovation of the crane, offering a deep understanding of when were cranes invented and how they evolved into their present form.

2025 Targeted Guide: How Often Does a Periodic Crane Inspection Occur?

This guide will provide a detailed explanation of how often does a periodic crane inspection occur,to ensure equipment safety and prevent accidents.