Bitumen Paver Machines: A Complete Guide to Smooth Road Construction

This article provides a comprehensive understanding of bitumen paver machines, covering basic knowledge to cutting-edge technologies.

Known as the "super ironing master" in road construction, the bitumen paver machine not only accurately paves hot asphalt mixtures but also directly determines the pavement's flatness, durability, and driving safety. Whether it's highways bearing tens of millions of vehicles, main roads ensuring urban commuting, or high-demand airport runways and parking lots, the bitumen paver machine is a "key player" in determining project quality whenever asphalt paver is involved. With its unique core advantages, it transforms loose asphalt mixtures into flat and durable road surfaces, making it a "cornerstone" equipment in modern transportation infrastructure construction.

What Is a Bitumen Paver Machine

The bitumen paver machine is an indispensable specialized heavy construction machinery in road construction. Its core mission is to evenly pave and initially compact heated asphalt mixtures, ultimately forming a flat road base or surface course. Its key advantages lie in "continuous operation + precise control" — while maintaining a stable speed, it enables a complete process of asphalt mixture from receiving and conveying to paving and initial compaction, laying a perfect foundation for the final compaction by road rollers.

1.Main Parts of a Bitumen Paver Machine

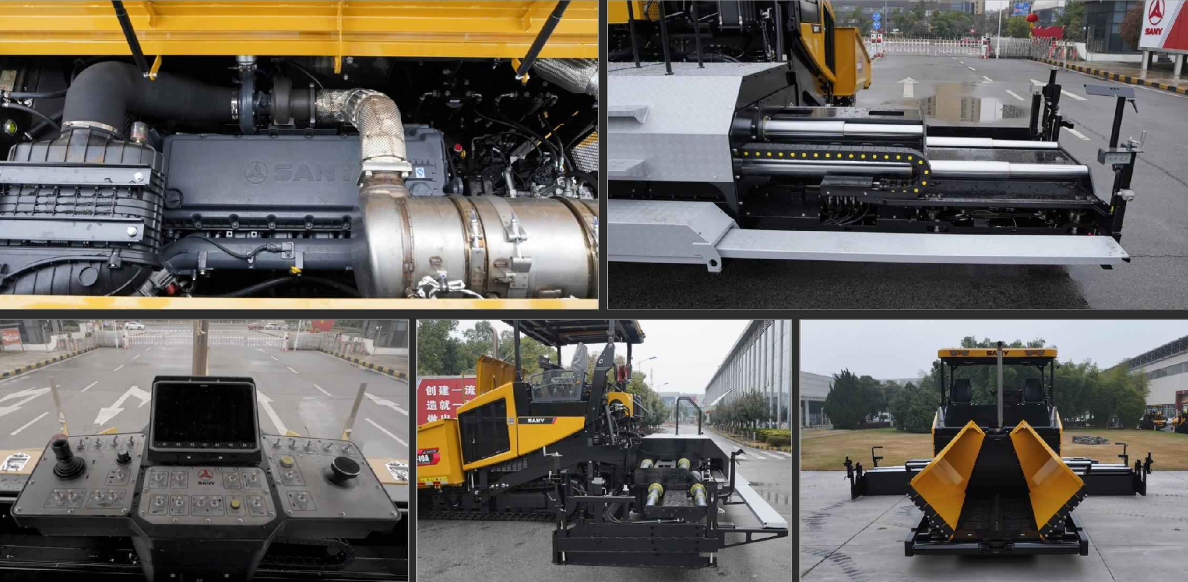

The efficient operation of a bitumen paver machine relies on the coordinated cooperation of various system components. Its core composition can be divided into 6 major systems, with key parts having clear functions:

- Power system: Centered on a 150-300kW diesel engine (some are lithium battery-powered), paired with hydraulic pumps to provide power for all movements of the entire machine, serving as the "heart" of the paver.

- Travel system: Includes crawlers/tires, drive motors, and transmission systems, responsible for driving the paver forward at a constant speed — crawler-type is suitable for complex road conditions, while tire-type is flexible and convenient.

- Feeding system: Composed of a hopper, scraper conveyor, and auger distributor, ensuring "sufficient material supply and uniform distribution".

- Paving system: The core is the screed, paired with a tamper bar and vibration device. It can not only smooth the mixture but also complete 10%-30% of initial compaction, making it the "key to a flat road surface".

- Control system: The operation console acts as the hub, equipped with buttons and display screens to adjust parameters such as speed and thickness; high-end models are equipped with an automatic leveling system, with a control accuracy of ±2mm.

- Auxiliary system: Includes heating system, spraying system, and cleaning system to ensure smooth operation.

2. Types of Bitumen Paver Machines

According to construction requirements, bitumen paver machines can be classified in 4 ways to accurately match different scenarios:

Classification Dimension | Specific Type | Core Features & Application Scenarios |

Travel Mode | Crawler Paver | Large contact area, strong stability; suitable for large-thickness (>15cm), large-width (>9m) projects like highways and airports. |

Tire Paver | Flexible steering, easy to move; suitable for small-width (<6m) construction like urban roads and railway sections. | |

Paving Width | Small (2-4m) | Compact body; suitable for community paths, rural roads, and parking lots. |

Medium (4-8m) | Balances efficiency and flexibility; used for urban main roads. | |

Large (8-16m+) | Extendable paving width; designed for wide-span construction like highways and airport runways. | |

Control Mode | Manual Control | Simple structure, low cost; suitable for simple projects or road repairs. |

Automatic Control | Equipped with intelligent leveling system, precise flatness control; standard for high-grade highway construction. | |

Structural Function | Standard Paver | Only basic paving and compaction functions; applicable to regular road construction. |

Multifunctional Paver | Integrates functions like emulsified asphalt spraying and glass fiber grid laying; improves integrated construction efficiency. | |

Modular Paver | Assembled adjustable structure; adapts to customized working conditions like ultra-wide bridge decks. |

How a Bitumen Paver Machine Works Step by Step

The operation process of a bitumen paver machine is closely interlocked, with the core being "continuous feeding → uniform material distribution → screeding and compaction → synchronous movement". It is specifically divided into 6 steps:

1. Construction Preparation

Debug parameters, preheat the screed to above 100℃, calibrate the automatic leveling system, and have dump trucks loaded with hot asphalt mixture (160-180℃) on standby.

2. Receiving Mixture

The truck dumps the hot mixture into the paver's hopper, with hydraulic flaps assisting in unloading. Operators monitor the material level to avoid material interruption or overflow.

3. Conveying Mixture

The scraper conveyor starts, continuously transporting the mixture in the hopper backward to the middle of the machine body. The conveying speed is linked and matched with the travel speed.

4. Uniform Material Distribution

The auger distributor rotates in the opposite direction, spreading the mixture to both sides and filling the "material trough" in front of the screed to ensure consistent material layer thickness within the paving width.

5. Screeding and Compaction

The paver moves forward at a constant speed, the screed maintains a fixed height, and the vibration/tamping device works at high frequency to screed the mixture and complete initial compaction. The automatic leveling system corrects deviations in real time.

6. Finishing Coordination

Road rollers follow closely to complete final compaction (compaction degree ≥95%), new trucks replenish materials in a timely manner to avoid "cold joints", and residual mixture on the equipment is cleaned after operation.

Latest Technology in Bitumen Paver Machines

Today, bitumen paver machines are upgrading towards the direction of "ultra-wide width, intelligence, energy conservation and environmental protection, and high precision". As an industry benchmark, SANY has applied these technologies to practical projects:

- Ultra-wide width: SANY paver SAP200C-10 achieves one-time paving forming of 19.25 meters. By adopting a frame screed with the torsion center coinciding with the resistance section, it ensures flatness during ultra-wide operation. Equipped with a 368kW high-power engine, it is suitable for heavy-duty working conditions such as high-speed reconstruction and expansion.

- Intelligence: SANY has also launched relevant products. Its SSP, SAP and other series of bitumen paver machines are equipped with intelligent supporting systems and services. Its unmanned paving and rolling machine group has passed digital construction tests and is about to be launched.

- Energy conservation and environmental protection: SANY SAP series models use construction big data for fuel consumption management, targeting the dual centers of the engine and hydraulic oil pump's fuel economy zone for iterative calculation. Combined with the optimized speed ratio transfer case, the engine and hydraulic oil pump always work in the efficient zone, which is more energy-saving and meets environmental protection requirements.

- High precision: All of SANY bitumen paver machines are equipped with ultrasonic sensors to monitor the material level, ensuring uniform distribution of the mixture and avoiding segregation that affects road strength. The SAP series is equipped with electric adjustment of the double-screw + guide sleeve height difference lifting mechanism, with a height difference adjustment stroke of 45mm, which can eliminate height difference camber in real time through electric adjustment. The camber adjustment range is 4%, and the telescopic baffle can be electrically adjusted to meet the construction camber requirement with one key, facilitating material control and solving material leakage.

Conclusion

From the collaborative work of basic components to complex step-by-step operations, from machine classification adapting to different scenarios to industry-leading technological innovations, the bitumen paver machine has always played the role of a "core executor" in road construction. With continuous breakthroughs in technologies such as intelligence, energy conservation and environmental protection, and ultra-wide width, enterprises like SANY are driving bitumen pavers towards higher efficiency, greater precision, and greener development through innovative practices, providing strong support for building higher-quality transportation networks. In the future, with the continuous empowerment of science and technology, the bitumen paver machine will usher in more breakthroughs. The flat roads paved by it will continue to carry the beautiful expectations of urban development and people's travel, becoming a "solid link" connecting various regions and promoting economic and social progress.

FAQs

Who Makes the Best Paving Machines?

In the field of paving equipment, SANY product quality is recognized as an industry benchmark and a cost-effective top choice. Its paving equipment combines strong performance, stable construction performance and comprehensive services, winning wide market recognition.

What Are the Main Types of Paver Machines?

Paver machines are mainly classified into four core dimensions—travel mode, paving width, control mode and structural function—to adapt to different construction scenarios:

- By travel mode: Divided into crawler-type and tire-type. Crawler-type has a large contact area and strong stability, suitable for large-thickness and wide-width projects such as highways and airport runways; tire-type features flexible steering and easy transfer, adapting to narrow urban roads or small-width construction.

- By paving width: Classified into small (2-4m), medium (4-8m) and large (8-16m+). Small machines are used for community roads and rural highways; medium machines are suitable for urban main roads; large machines can expand width through telescopic screeds, specially designed for wide-span construction like highways and airports.

- By control mode: Split into manual and automatic control. Manual models have a simple structure and low cost, suitable for simple projects or road repairs; automatic models are equipped with laser/GPS leveling systems to precisely control flatness, serving as standard equipment for high-grade highway construction.

- By structural function: Including standard pavers, multifunctional pavers and modular pavers.

What Machine Is Used to Flatten Asphalt?

The core equipment for compacting asphalt is the asphalt road roller. As a key machine in the "paving-compacting" process of asphalt pavement construction, it eliminates gaps in asphalt mixtures and enhances aggregate adhesion through physical compaction, ultimately ensuring the pavement's density, flatness and durability.

Featured Products

Recommend Blogs

2026 Asphalt Paver Company: Business, Processes & Selection Guide

How to choose an Asphalt Paver Company? This article analyzes core services, construction processes, shares selection tips, helps control project quality.

Quick Selection Guide: Detailed Explanation of Paver Mean

This guide will help you fully understand what a paver mean is, so that you can make informed decisions and select suitable equipment for your road-paving project.