What Are the Wheels on a Crane with Open Grooves? Analysis of Important Components of Cranes in 2025

What are the wheels on a crane with open grooves? What types of wheels exist, and how should they be maintained? This article will help you better understand these essential crane components.

On construction sites and port terminals, cranes are a common sight. They can effortlessly lift dozens of tons, efficiently handling material transportation and equipment installation. Among the many complex and precise parts of a crane, what are the wheels on a crane with open grooves? What categories of wheels are there? Understanding them gives us deeper insight into the working principles and operating mechanisms of cranes. Let’s take a closer look.

What Are the Wheels on a Crane with Open Grooves?

The wheels on a crane with open grooves are commonly referred to as pulleys. They play a critical role in a crane’s operation, with the grooves designed to accommodate ropes or steel cables. By redirecting forces, these pulleys assist the crane in lifting and moving heavy loads, making them one of the key components in the crane’s hoisting system.

Types of Crane Pulleys (Grooved Wheels)

1. Single-Grooved Pulley

- Structural Features: A single-groove pulley has only one groove for a rope or steel cable. Its design is relatively simple and manufacturing is straightforward. The pulley body typically consists of a hub, spokes, and a rim (grooved section), commonly made of cast iron, cast steel, or nylon.

- Applications: Often used in small cranes or in compact works paces with lower lifting requirements, such as simple lifting equipment on small construction sites or home-use hoists. Single-groove pulleys are also used in auxiliary structures of larger cranes, such as guiding the wire rope in the outrigger system of truck-mounted cranes.

2. Double-Groove Pulley

- Structural Features: Equipped with two parallel grooves for ropes or steel cables, double-groove pulleys are more complex than single-groove versions and require higher manufacturing precision to ensure smooth operation of both ropes. Material selection is similar to single-groove pulleys, based on usage conditions and cost considerations.

- Applications: Commonly used in medium-sized cranes, especially where lifting stability and safety are critical. For example, medium-sized portal cranes at ports often use double-groove pulleys with dual rope systems to improve load stability and reduce sway. They are also applied in the luffing mechanism of tower cranes to ensure smooth operation.

3. Multi-Groove Pulley (Three or More Grooves)

- Structural Features: Multi-groove pulleys have three or more grooves, with complex design and tight manufacturing tolerances regarding groove spacing, depth, and profile. Typically made of high-strength cast steel to handle large loads without deformation under multi-rope tension.

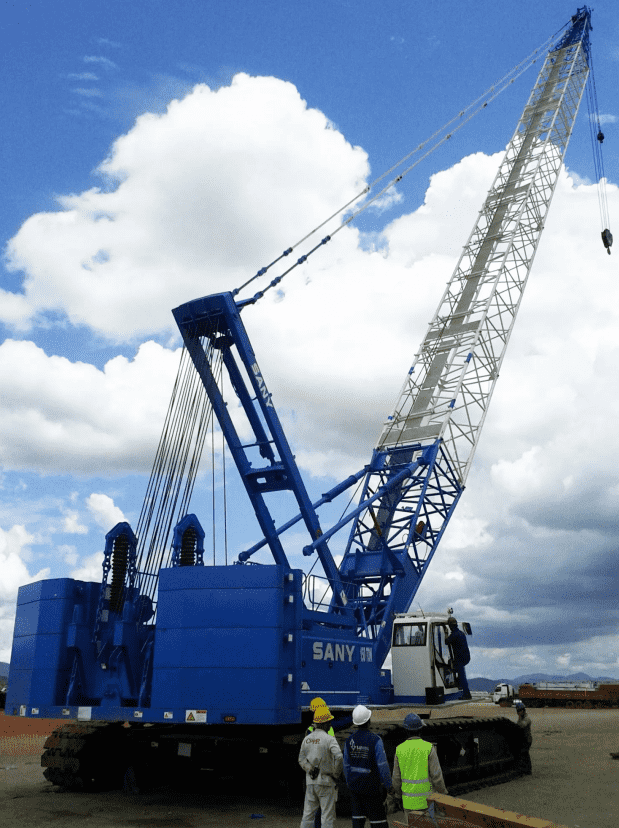

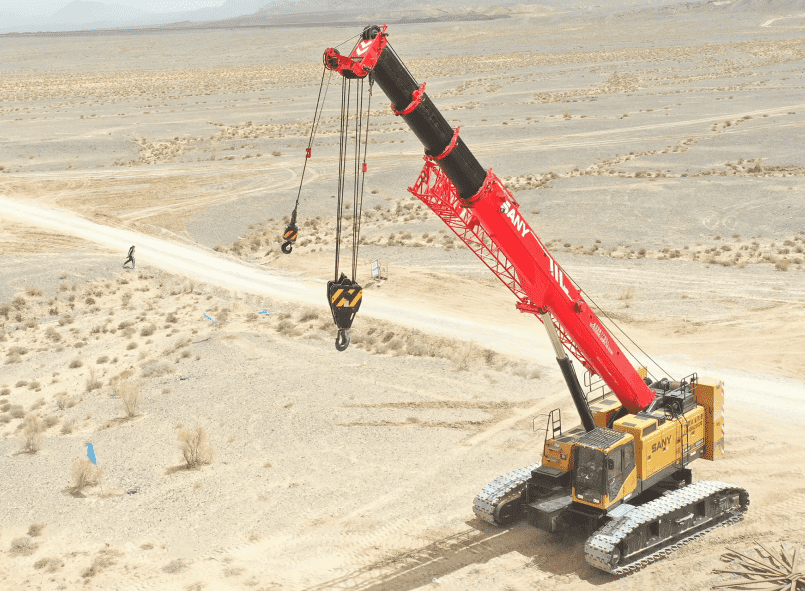

- Applications: It is mainly used in large and heavy cranes. For example, in wind power installation cranes, since it is necessary to lift huge wind turbine components and the lifting weight is large, SANY crawler crane will use multi-groove pulleys to form a complex pulley system to meet the lifting requirements.

Types of Crane Wheels (Ungrooved Travel Wheels)

1. Ungrooved Wheels

- Structural Features: Smooth cylindrical tread without side flanges, simple in design and easy to manufacture.

- Core Function: Minimizes friction between wheel flanges and tracks, suitable for systems with additional guidance mechanisms.

- Typical Applications: Small trolley wheels on single-girder cranes (e.g., bridge crane trolleys) or moving components of automated logistics cranes requiring light-load, low-resistance movement.

2. Single-Flange Wheels

- Structural Features: Only one side has a vertical flange, usually 15-30 mm high, forming a single-side limit.

- Core Function: Provides moderate anti-derailment capability while reducing friction from dual flanges. Suitable for precise track alignment scenarios.

- Typical Applications: End beam wheels on small gantry cranes, slewing wheels on tower cranes, or auxiliary wheels on light to medium cranes.

3. Double-Flange Wheels

- Structural Features: Flanges on both sides of the wheel, forming a "grooved" structure with the tread in between, the most common type.

- Core Function: Dual-flange design offers strong anti-derailment, suitable for tracks with moderate precision or where lateral impact may occur.

- Typical Applications: Main travel wheels of most heavy-duty cranes, such as bridge crane trolleys, end beams of large gantry cranes, crawler crane tracks, and port container crane wheels.

When to Use Pulleys and Travel Wheels?

1. Scenarios for Using Pulleys

The primary function of a pulley is to change the direction of force, reduce effort, or improve operational precision by utilizing ropes or steel cables. Therefore, pulleys are essential whenever vertical lifting or horizontal luffing of heavy loads is involved.

Heavy Load Lifting

This is the primary application for pulleys, and almost all cranes rely on pulley systems for lifting mechanisms. For example, when a crane is lifting containers or rebar, a combination of fixed and movable pulleys reduces the load on the motor or hydraulic system while stabilizing the lifting speed to avoid swaying.

Heavy Load Luffing

When adjusting the horizontal position of a load, pulleys guide the ropes to enable luffing. For instance, in the luffing mechanism of a tower crane, double-groove pulleys work with the ropes to move the trolley along the jib, changing the horizontal position of the load and ensuring it reaches the target location accurately.

Balancing and Guiding Needs

When multiple ropes are used to share the load, balance pulleys are used to evenly distribute the tension to prevent overload and rope breakage. Fixed pulleys also act as guide wheels, changing the direction of ropes to suit the crane’s structural layout.

2. Scenarios for Using Travel Wheels

The primary role of travel wheels is to move the crane either fully or partially, allowing it to cover a wider operational area by contacting the tracks or ground. There are two specific scenarios for their use:

Overall Movement: Expanding the Operational Area

When the crane needs to move across a large area within a fixed site, travel wheels work with tracks or the ground to facilitate this movement.

Local Movement: Precise Adjustment of Work Points

When the crane itself remains stationary, but its trolley needs to move laterally to align with a load, small travel wheels are installed on the trolley. These wheels are typically compact and high-precision, some even ungrooved (requiring guide wheels to prevent derailment), ensuring smooth movement.

Pulley and Wheel Maintenance Tips

1. Pulley Maintenance Tips

Daily Checks

Before operation, operators should measure the wear depth of the rope grooves using calipers.. If the wear exceeds 1/10th of the steel rope diameter, or if there are uneven wear, cracks, or deformations in the grooves, the pulley should be replaced immediately. Manually rotate the pulley—if there’s any sticking, strange noises, or increased resistance, it suggests the bearing is lacking lubrication or the bushing is worn, and the internal parts need to be inspected.

Lubrication Maintenance

It is recommended to lubricate the pulley every month, focusing on the rolling bearings or sliding bushings inside the pulley, as well as the contact surfaces between the pulley and shaft.

Fault Repair and Replacement

If there are minor scratches on the groove, smooth them out with fine sandpaper to avoid damaging the steel rope. If the bushing is lightly worn, apply a wear-resistant coating to extend its lifespan temporarily. If the pulley has cracks, excessive groove wear, a seized bearing, or severe bushing deformation, the entire pulley must be replaced. The material and rated load of the new pulley must match the original model, and mixing different specifications is prohibited.

2. Wheel Maintenance Tips

Daily Checks

After heavy-duty operations, inspect the wheel tread for wear, dents, peeling, or cracks. If the wear exceeds 5% of the original diameter, or if the tread has dents deeper than 3mm, the crane must be shut down for maintenance.

Track Cleaning

Debris and obstacles on the crane’s tracks can cause excessive wheel wear and increase derailment risks. It’s essential to regularly clear debris from the tracks and ensure proper alignment.

Lubrication Maintenance

Lubricate the wheel hub bearings, the contact surfaces between the wheels and shafts, and the track surface once per month. Rotate the wheels manually to ensure even lubrication.

Fault Repair and Replacement

If deviations occur in wheel installation, adjust the horizontal or vertical misalignment accordingly.If the track is uneven, grind the track joints or adjust track height. When the wheel tread is severely worn, the flange is broken, the bearing is seized, or the wheel has cracks, the entire wheel must be replaced.

Conclusion

Now that we have explored what are the wheels on a crane with open grooves, their types, and their routine maintenance methods, we can operate and use cranes more effectively and safely in the future, while also extending their service life.

FAQs

Are the wheels on the crane with open grooves?

Whether a crane has wheels with open grooves depends on the specific type. Wheels with open grooves are primarily pulleys, used in the lifting system to guide the steel cables through the groove. On the other hand, the travel wheels, which support the crane's movement along tracks, are typically grooveless and rely on the wheel flange to limit movement.

What are the wheels on a crane with open grooves that robes or cables fit around?

The wheels with open grooves that accommodate ropes or steel cables are called pulleys. They are a core component of the crane's lifting system, with the open grooves precisely guiding the steel cables to prevent misalignment or detachment. Their primary function is to change the direction of the steel cable's force, and through multiple pulley systems, they help reduce effort, improving both the lifting efficiency and safety of the crane.

What are the wheels on a crane called?

There are two main types of wheels on a crane:

The wheels in the lifting system, which have grooves for ropes or steel cables, are called pulleys.

The wheels at the base of the crane, which roll along tracks and move the machine, are called travel wheels.

What are crane wheels made of?

Crane wheels are commonly made from two types of materials:

Cast steel, which is suitable for high-tonnage, heavy-load scenarios due to its high strength and wear resistance.

Ductile cast iron, which is used in medium and small-load cranes. It is more cost-effective and offers better toughness.

In certain specialized applications, alloy steel may also be used to enhance performance.

Featured Products

Recommend Blogs

2025 Targeted Guide: How Often Does a Periodic Crane Inspection Occur?

This guide will provide a detailed explanation of how often does a periodic crane inspection occur,to ensure equipment safety and prevent accidents.

Types of Cranes: Your 2025 Comprehensive Guide to Every Major Category

As 2025's latest authoritative guide to types of cranes, this article breaks down the four types' core traits and application differences, giving engineers and equipment purchasers key selection criteria

How Are Cranes Built? A Step-by-Step Guide to the Construction Process

Cranes help us build towering skyscrapers, yet few know how cranes are built. This guide takes you through an in-depth exploration of the process